Introduction

In the ever-evolving realm of radio frequency (RF) technology, connectors play a pivotal role in enabling seamless and reliable signal transmission. Among the vast array of connectors available, SSMA (SubMiniature A) connectors stand out as high-performance screw-on connectors designed for operation from DC to an impressive 35 GHz, with the capability to extend their performance up to 40 GHz. Introduced in 1960, SSMA connectors are a miniature evolution of the widely used SMA (SubMiniature version A) connectors, featuring a 10-36 threaded coupling mechanism. These connectors adhere to rigorous standardization and specification criteria, including CECC 22 160, MIL-PRF-39012, and MIL-STD-348, ensuring their reliability and compatibility. In this comprehensive guide, we will explore the world of SSMA connectors, examining their design, technical specifications, key features, applications across diverse industries, interface standards, and their role in the fields of Mil-Aero, Telecommunication, RFID, Radar systems, and Test & measurement.

SSMA Plug Connectors

![ssma plug ra rg401]()

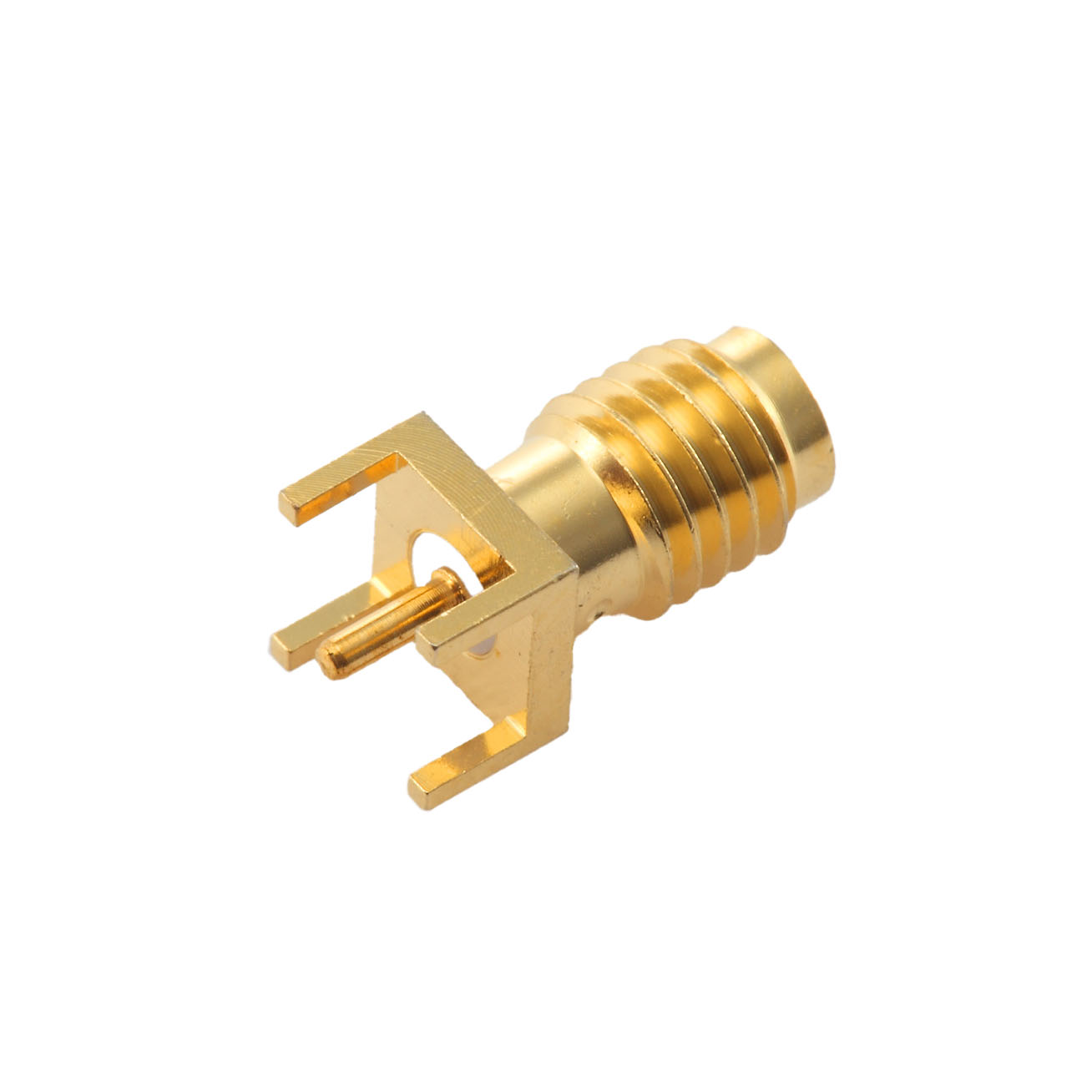

SSMA Jack Connectors

![ssma jack pcb]()

Understanding SSMA Connectors

1. Design and Construction

SSMA connectors represent a compact yet powerful evolution of their SMA predecessors. These connectors feature a threaded coupling mechanism with a 10-36 threaded interface. The threaded coupling ensures a secure and robust connection, making SSMA connectors suitable for applications demanding precision and reliability, particularly in high-frequency environments.

2. Technical Specifications

To gain a comprehensive understanding of SSMA connectors, it is essential to delve into their key technical specifications:

Frequency Range: DC to 35 GHz (Extendable up to 40 GHz)

Impedance: 50 Ohm

Dielectric Withstanding Voltage: 750 VRMS

Connector Durability: Over 500 mating cycles

Power Handling: 0.60 kW - 10 kW max

Temperature Range: -65°C to +165°C

These specifications define the impressive electrical performance, high-frequency capabilities, temperature tolerance, durability, and power handling capacity of SSMA connectors, making them an ideal choice for demanding RF applications.

Key Features of SSMA Connectors

SSMA connectors offer a range of key features that make them suitable for high-frequency applications across various industries:

1. Exceptional Frequency Range

With a frequency range spanning from DC to 35 GHz, with extendable performance up to 40 GHz, SSMA connectors excel in high-frequency applications, ensuring reliable signal transmission and reception in demanding RF environments.

2. Precise Impedance Matching

SSMA connectors feature a 50 Ohm impedance, providing precise impedance matching for RF components and equipment, ensuring minimal signal loss and optimal performance.

3. Robust Dielectric Withstanding Voltage

With a maximum dielectric withstanding voltage of 750 VRMS, SSMA connectors offer robust insulation, enhancing their reliability and safety in high-voltage applications.

4. Exceptional Durability

SSMA connectors are designed to withstand over 500 mating cycles, ensuring their longevity and dependable performance in diverse applications.

5. Impressive Power Handling Capacity

SSMA connectors can handle power levels ranging from 0.60 kW to a maximum of 10 kW, making them suitable for high-power RF applications.

6. Wide Temperature Tolerance

SSMA connectors exhibit a wide temperature range, with the ability to operate reliably in temperatures ranging from -65°C to +165°C. This tolerance makes them suitable for applications in extreme environmental conditions.

Applications of SSMA Connectors

SSMA connectors have found applications across a multitude of industries, owing to their high-frequency capabilities, precision, and durability. Some notable applications include:

1. Mil-Aero (Military-Aerospace)

In the Mil-Aero sector, SSMA connectors are crucial components for ensuring reliable RF connectivity in military aircraft, satellites, communication systems, and radar applications, where precision and high-frequency performance are essential.

2. Telecommunication

Telecommunication networks rely on SSMA connectors for connecting RF components and equipment, ensuring seamless communication in both wired and wireless networks.

3. RFID (Radio-Frequency Identification)

RFID systems utilize SSMA connectors to establish robust connections between readers, antennas, and tags, enabling efficient data exchange and tracking across a variety of industries, including logistics and supply chain management.

4. Radar Systems

SSMA connectors play a pivotal role in radar systems, where their high-frequency capabilities and secure connections are essential for accurate signal transmission and reception.

5. Test & Measurement

Laboratories and test facilities utilize SSMA connectors for connecting RF test and measurement equipment, ensuring precise and repeatable results in research, development, and quality control processes.

Interface Standards

SSMA connectors adhere to stringent interface standards and specifications, ensuring their compatibility and performance reliability. Some of the key interface standards include:

CECC 22 160: This European standard defines the requirements for RF connectors, ensuring their quality and compliance with industry standards.

MIL-PRF-39012: This U.S. military specification establishes the performance and quality requirements for RF connectors, making them suitable for military applications.

MIL-STD-348: This U.S. military standard sets forth the dimensional and performance requirements for RF connectors, ensuring their compatibility and reliability in military systems.

Conclusion

SSMA connectors, with their high-frequency capabilities, precision, and durability, have earned their place as indispensable components in the world of RF technology. Their impressive electrical performance, wide temperature tolerance, and adherence to rigorous interface standards make them the preferred choice for engineers, designers, and technicians working on diverse applications.

As technology continues to advance and the demand for high-frequency RF connectors grows, SSMA connectors remain at the forefront, serving as reliable and efficient solutions for a wide range of industries, including Mil-Aero, Telecommunication, RFID, Radar systems, and Test & measurement. Their ability to deliver precise and secure connections, even in demanding RF environments, ensures that they will continue to play a crucial role in enabling seamless and dependable signal transmission in the ever-evolving landscape of RF technology.