The TestLink RF Test Cable Assemblies are engineered to meet high standards in attenuation, phase stability, and durability, making them ideal for test and measurement applications. Equipped with purpose-designed connectors, they feature a specialized connection process that ensures low and stable VSWR, along with robust cable protection against mechanical stress.

The connector bodies and nuts are crafted from stainless steel, providing exceptional durability with a high number of mating cycles. These features make TestLink cables the perfect choice for laboratory or production environments, where reliable signal testing is conducted frequently.

The TestLink Cable Assembly Family

Series | Frequency | Connector |

ZUT06 | 6 GHz | SMA,N ,TNC ,BNC Connector |

ZUT26 | 26.5 GHz | 3.5 mm, SMA, N, TNC Connector |

ZUT26P | 26.5 GHz Armour Cable | 3.5 mm, SMA, N, TNC Connector |

ZUT40 | 40 GHz | 2.40 mm, 2.92 mm Connector |

ZUT40P | 40 GHz Armour Cable | 2.40 mm, 2.92 mm Connector |

ZUT50 | 50 GHz | 2.40 mm, 2.92 mm Connector |

ZUT50P | 50 GHz Armour Cable | 2.40 mm, 2.92 mm Connector |

ZUT67 | 67 GHz | 1.85 mm Connector |

ZUT67P | 67 GHz Armour Cable | 1.85 mm Connector |

ZUT110 | 110 GHz | 1.0 mm Connector |

| ZUT110P | 110 GHz Armour Cable | 1.0 mm Connector |

![application-2 application-2]() Applications:

Applications:

•Laboratory test and measurement

•Production line testing

•Field test and measurement

![features2]() Key Features:

Key Features:

•High stability

•100% tested for reliability

•Superior electrical performance

•Precision connectors

•Extended mating cycles

•Heat-resistant and flame-retardant design

•Armoured jacket available

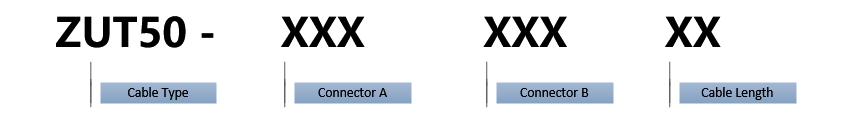

Ordering Guide

![Ordering guide-name system ZUT50]()

Connector Code | Description |

2.92J | 2.92 mm male |

2.92K | 2.92 mm female |

2.4J | 2.4mm male |

2.4K | 2.4 mm female |

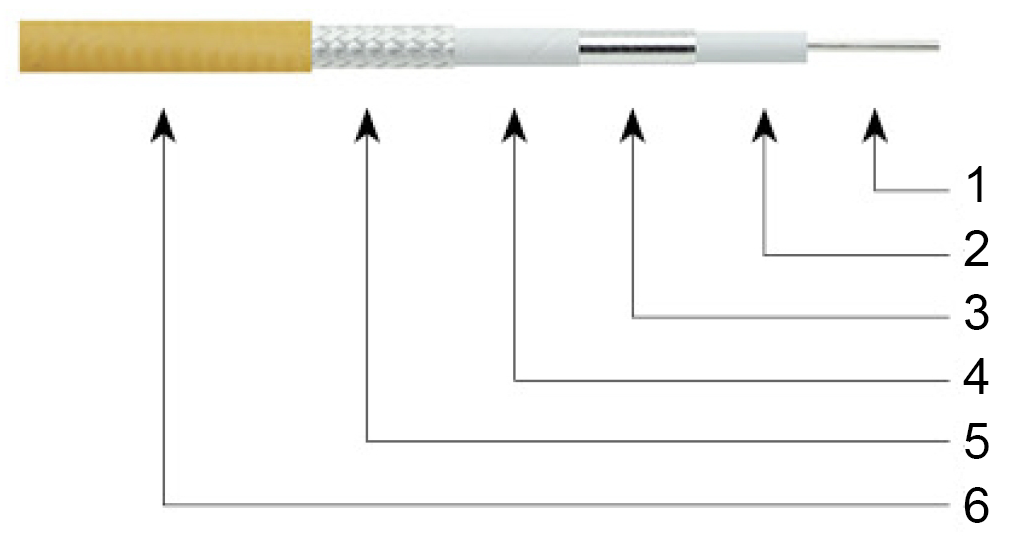

![cable structure]() Cable Construction

Cable Construction

![zt40 cable]()

Part No | ZUT50 |

Cable Construction |

No |

| Material & Surface Finish |

1 | Conduct: | Silver plated cooper wire |

2 | Insulator: | LD-PTFE |

3 | Inner Braiding: | Silver plated cooper ribbon |

4 | Interlayer | LD-PTFE |

5 | Outer Braiding: | Silver plated cooper braiding |

6 | Jacket Jacket: | FEP |

![CABLE AND JUMPER]() Mechanical & Electrical Parameter

Mechanical & Electrical Parameter

Mechanical Characteristic |

Dimension | mm | Inch |

Conduct | 0.72 | 0.028 |

Insulator | 2.21 | 0.087 |

Inner Braiding | 2.38 | 0.094 |

Interlayer | 2.68 | 0.106 |

Outer Braiding | 3.14 | 0.124 |

Jacket | 3.6 | 0.142 |

Weight | 0.031kg/m |

Minimum Bending Radius | (Dynamic 36.0mm),(Static 18mm) |

Cycle | > 5000 |

Temperature Range | -55℃ - +165℃ |

Electrical Characteristic |

| Connector | 18GHz | 26.5GHz | 40GHz | 50GHz |

Maximum VSWR | 2.92mm | 1.20:1 | 1.25:1 | 1.25:1 | -- |

| 2.4mm | 1.20:1 | 1.25:1 | 1.25:1 | 1.30:1 |

Impedance | 50 Ω |

Velocity Propagation | 76% |

Shielding Efficiency | > 90 dB |

Amplitude Stability | < ±0.05dB@50GHz |

Phase Stability | < ±5°@50GHz |

Attenuation(25℃) |

Frequency(MHz) | dB/100ft | dB/100m |

1000 | 14.66 | 48.1 |

3000 | 25.57 | 83.9 |

6000 | 36.39 | 119.4 |

12400 | 52.85 | 173.4 |

18000 | 64.07 | 210.2 |

26500 | 78.36 | 257.1 |

40000 | 97.29 | 319.2 |

50000 | 109.48 | 359.2 |

Average power (25℃,sea level,only cable) |

Frequency(GHz) | Watts |

1000 | 506 |

3000 | 290 |

6000 | 204 |

12400 | 140 |

18000 | 116 |

26500 | 95 |

40000 | 76 |

50000 | 68 |

LenoRF ensures that TestLink cables deliver unmatched performance for all RF testing needs

Each cable undergoes rigorous individual testing and is delivered with a comprehensive test report.

FAQ

Sample Delivery Time

Regular models require 15 days, while some complex connectors require 25 days.

Sample Fee

Most RF connectors are CNC-machined parts and do not require mold-making.

However, each part needs to be fine-tuned on the CNC machine. Typically, a single sample costs $200.

This fee will be refunded after a 5K bulk order.

Guarantee

Brass RF connectors come with a one-year warranty.

Stainless steel connectors come with a three-year warranty.

The lifespan also depends on the contact material beryllium contacts offer better durability.

ROHS & REACH Compliance

Our products fully comply with ROHS & REACH regulations.

Does LENORF Offer Military-Grade Products?

Yes. We are honored to provide military-grade products with exceptionally stable quality.

MOQ (Minimum Order Quantity)

Regular connectors: 500 PCS

Adapters: 100 PCS

Military connectors: 100 PCS

Materials

Common materials include:

Body: Brass, stainless steel

Insulator: PTFE, PEEK

Contacts: Brass, phosphor bronze, beryllium copper

Other: Aluminum, titanium alloy

What is VSWR, and why does it matter?

VSWR (Voltage Standing Wave Ratio) indicates signal reflection. Ideal: 1.0 (perfect match). Lower VSWR means less signal loss and distortion.

What are typical applications of RF connectors?

Telecom (5G, LTE, satellite) Aerospace & defense (radar, avionics, secure comms) Test & measurement (network/spectrum analyzers) Broadcast & video distribution Automotive radar and IoT devices Medical imaging & equipment

What is the difference between RF connectors and coaxial connectors?

They are often used interchangeably. However: Coaxial connector refers to the physical design (shielded cylindrical form). RF connector emphasizes its use in radio-frequency applications. Most RF connectors are coaxial.

What is “reverse polarity” (RP-SMA, RP-TNC)?

Reverse polarity means the gender of the center pin is swapped while keeping the outer body style unchanged. It was introduced to comply with regulatory requirements in Wi-Fi devices and to prevent connection with standard SMA/TNC.