Introduction

In the realm of radio frequency (RF) technology, connectors play a pivotal role in ensuring seamless signal transmission. Among these connectors, the TNC (Threaded Neill-Concelman) connector stands out as a versatile and widely used option. Designed as a threaded variation of the BNC connector, TNC connectors are known for their excellent vibration handling capabilities and are frequently employed in applications where electrical performance and mechanical durability are paramount. In this comprehensive guide, we will delve into the intricacies of TNC connectors, exploring their design, applications, technical specifications, and notable interface standards. Additionally, we will address the factors influencing their maximum operating frequency and impedance variations.

TNC Plug Connector

![25chn00000173, tnc plug crimp lmr240]()

TNC Jack Connector

![20-811 ,TNC JACK CRIMPING RG58-142-223]()

Understanding TNC Connectors

1. Design and Construction

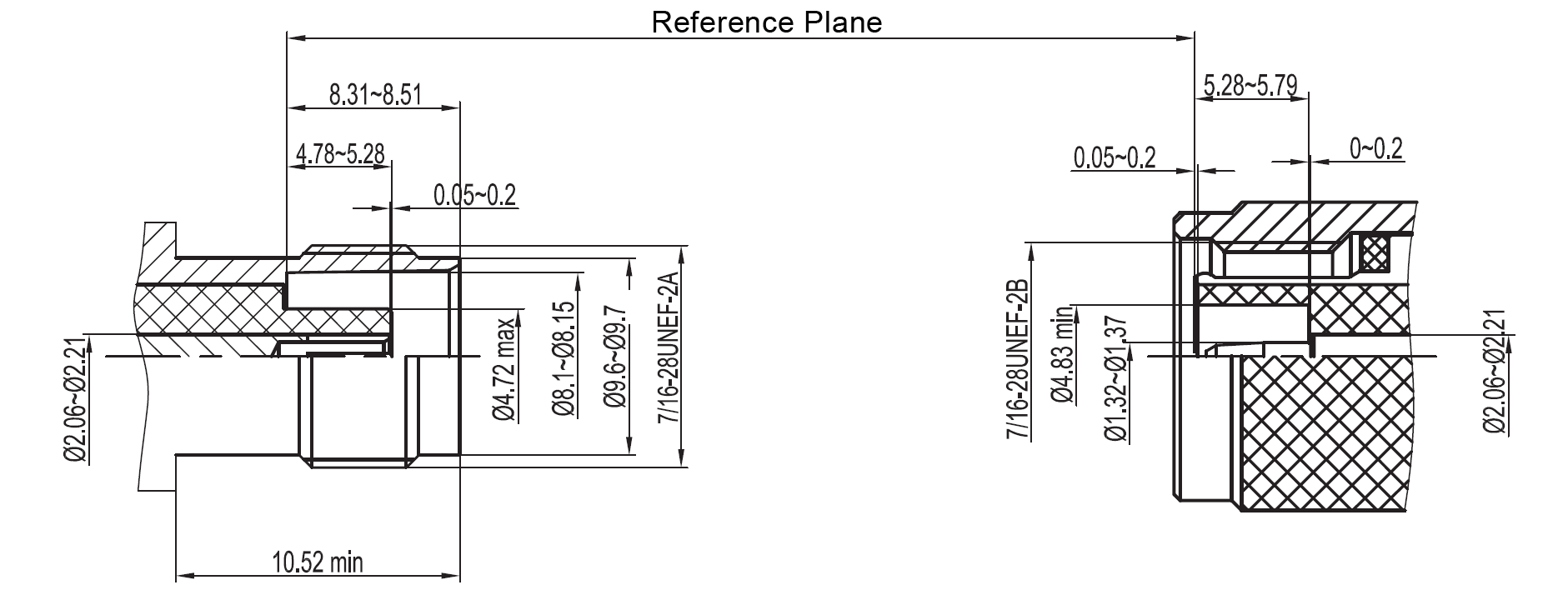

TNC connectors, short for Threaded Neill-Concelman connectors, are characterized by their threaded coupling mechanism, setting them apart from their BNC counterparts. This threaded coupling is achieved through a 7/16 - 28 UNEF (Unified National Extra Fine) threading, which provides exceptional resistance to vibration, making TNC connectors ideal for use in environments where mechanical stability is essential.

2. Technical Specifications

To comprehend the capabilities and limitations of TNC connectors, it is imperative to examine their key technical specifications:

Impedance: 50 Ω

Maximum Operating Frequency: 11.00 GHz

Coupling Mechanism: Screw-on Coupling

These specifications define the connector's electrical performance, frequency range, and coupling mechanism, making TNC connectors highly adaptable for various applications.

3. Variations in Impedance

The TNC series primarily exhibits a characteristic impedance of 50 Ω, which is the standard impedance value for most TNC connectors. However, it is important to note that 75 Ω variations of TNC connectors do exist, although they are relatively uncommon. These 75 Ω variants can be identified by the reduced amount of dielectric material inside the interface, a crucial distinction to consider when selecting the appropriate connector for a specific application.

Maximum Operating Frequency of TNC Connectors

The maximum operating frequency of TNC connectors is a critical aspect of their performance and is influenced by various factors, including design precision and commercial manufacturer specifications. While TNC connectors can theoretically support performance up to 11 GHz, practical limitations often come into play.

1. Precision Designs

In precision designs and applications where meticulous attention is given to connector construction, TNC connectors can indeed achieve their maximum operating frequency of 11.00 GHz. These precision designs are characterized by high-quality materials, precise tolerances, and stringent manufacturing standards, ensuring optimal electrical performance.

2. Commercial Manufacturer Specifications

In commercial settings, TNC connectors are often subject to manufacturer specifications that may set a maximum operating frequency range. Typically, these specifications fall within the 3 to 6 GHz range, which is more than adequate for many common applications. However, it is essential for users to consult manufacturer data sheets and specifications to determine the precise frequency range of a particular TNC connector.

Applications of TNC Connectors

TNC connectors find extensive use in various applications across industries due to their electrical performance, mechanical durability, and threaded coupling mechanism. Some notable applications include:

1. Aerospace and Defense

In the aerospace and defense sectors, TNC connectors are favored for their robust design and exceptional vibration handling capabilities. They are commonly employed in radar systems, communication equipment, and military-grade electronics where reliability and ruggedness are paramount.

2. Telecommunications

TNC connectors are also found in telecommunications equipment, particularly in high-frequency applications. They play a crucial role in establishing reliable connections for cellular base stations, satellite communication systems, and microwave links.

3. Test and Measurement

TNC connectors are a popular choice for test and measurement equipment, such as spectrum analyzers and network analyzers. Their ability to maintain precise electrical characteristics at high frequencies makes them essential for accurate measurements.

4. Wireless Technologies

Wireless technologies, including Wi-Fi and RF transceivers, often rely on TNC connectors for connecting antennas and other RF components. TNC connectors provide the necessary performance and durability for stable wireless connections.

Interface Standards

![tnc interface drawing]()

TNC connectors adhere to several interface standards, ensuring compatibility and interchangeability across different manufacturers and applications. Notable interface standards for TNC connectors include:

MIL-PRF-39012: A military specification that outlines the requirements for TNC connectors used in military and aerospace applications.

IEC 60169-17: An international standard that defines the dimensions and technical characteristics of TNC connectors.

CECC 22200: A European standard specifying the electrical and mechanical requirements of TNC connectors.

DIN EN 122200: A German standard that aligns with IEC 60169-17, ensuring consistency in TNC connector specifications.

Conclusion

In the world of RF connectors, TNC connectors stand as a testament to the importance of design precision, electrical performance, and mechanical durability. Their threaded coupling mechanism, excellent vibration handling, and ability to operate at frequencies up to 11 GHz make them a versatile choice for a wide range of applications, spanning from aerospace and defense to telecommunications and wireless technologies.

While TNC connectors are characterized by their standard 50 Ω impedance, it is essential to be aware of the existence of 75 Ω variants, identifiable by differences in dielectric material. Additionally, users should consider manufacturer specifications when determining the maximum operating frequency of a specific TNC connector.

As technology continues to advance and the demand for high-frequency RF connections grows, TNC connectors remain a reliable and adaptable choice for engineers and professionals seeking to establish robust and efficient RF connections in their applications. Their adherence to international interface standards ensures compatibility and interchangeability, further solidifying their place in the world of RF technology.